The bark spud is an iron tool used to remove bark from cut timber. Most bark spuds have a steel head with a hard wooden handle. The head is rounded or dish-shaped and has one cutting edge. The sharp wedge on the end of the bark spud slides between bark and wood on a log and helps to peel the bark off in long strips. In Wisconsin, men peeled bark from hemlock trees in spring and summer. In winter, they piled the bark onto sleds and took it to the tanneries. The sleds could weigh as much as 23 tons! This bark spud is from the Kuse Farm Museum and Nature Preserve in Medford, WI in Taylor County.

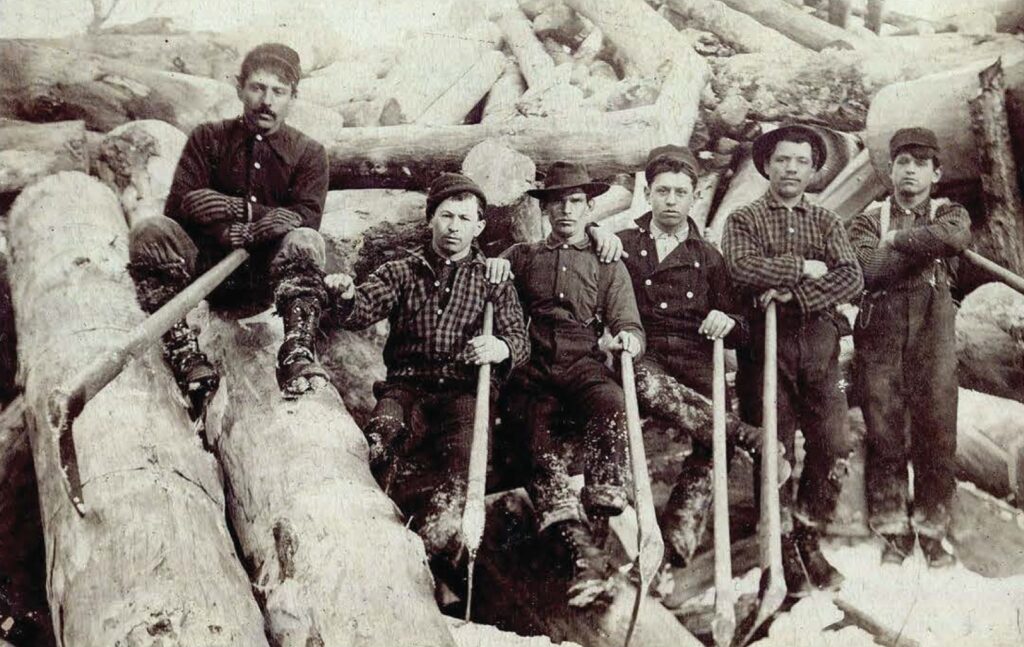

Peeling Bark for Cash in Taylor County

The Kuse family moved to Medford in 1883 at the start of the tanning boom in the area. Although they farmed during the summer, in Taylor County peeling bark was a common way to earn extra money during the spring. It is easiest to peel bark during spring and summer months when the sap is running. Peeling bark was a way for families to earn extra income during slow periods, and the Kuse family likely used the bark spud for this purpose.

When the Kuse family moved to Medford, the bark spud was likely used for peeling bark from hemlock trees for the local tanning industry. The tanning industry thrived in the cutover areas of northern Wisconsin. After logging companies had cut the most valuable stands of white pine, they left less valuable stands of hardwoods like oaks and hemlocks, which were then peeled of their bark.

The tanning boom in Taylor County declined by the 1920s, and with it the demand for hemlock bark. In the next decades, the first generation of softwoods that grew in the cutover areas matured, and by the 1960s they had grown large enough to harvest. In the 1960s and 1970s, people in Taylor County took up their bark spuds once again. This time they peeled the bark from softwoods like aspen and birch. Peeling aspen bark was known as “peeling popple” and instead of selling the bark this time, Taylor County residents sold the peeled wood to the paper companies. Paper companies used peeled spring aspen to make high quality paper tissues.

Tanning Hides with Bark

Although a bark spud was a useful and commonplace object in any Wisconsin logging camp, it has a special relationship with the hemlock lumbering and leather tanning industries that developed in Taylor County.

After most of the pines in northern Wisconsin were felled, logging companies looked for new ways to continue their work, hoping to make money on the remaining stands of oak and hemlock. Some companies turned to making oak furniture, others began to mine iron ore, and still others began to harvest hemlock bark for tanning.

Oak, hemlock, and chestnut trees all produce tannin, a bitter chemical that protects the trees against insects. For millennia, people have extracted the tannin from trees and used it to preserve animal hides to make leather. Tanners used the chemicals in hemlock bark to alter the protein structure of cow hides to make the hides more durable, flexible, and long-lasting. The process is called tanning.

To tan leather, tanners soak the hide to loosen the hair, scrape it to remove hair, and then soak the hide in a vat filled with water and bark. After soaking in the vat for a day or so, the hides are hung up to dry. This process could be very smelly, and the run-off water from the tanning vats was unsafe to drink.

The tanners in Taylor County use cow hides to make high quality leather for boots and horse tackle. Other tanneries specialized in tanning other kinds of animal hides. In the video below, the workers are tanning sheep hides to make expensive women’s gloves.

Written by Hildegard Kuse and Loretta Kuse, April 2019.

How to: Peel Bark

In this video, Wesley Bushor demonstrates a job that he had as a young logger: peeling poplar trees.

Click on the video title (at left) to open in YouTube.

Kuse Farm Museum & Nature Preserve

This object is part of the Kuse Farm Museum Collection in Medford, Wisconsin. Research for this object essay and its related stories was supported by the museum.