Tanning in Taylor County

In early 1890, members of a wealthy Boston-based family, the Shaws, visited Wisconsin to find new sources for the tannic acid needed to produced leather for horse harnesses and boots. The Shaw Family operated tanneries in Maine, Massachusetts, and Canada, and were looking for a new place to do business. They chose Taylor County for their new operation because the county had many forests, was close to several tanneries, and had access to both the Soo Line and Chicago-based railroads.

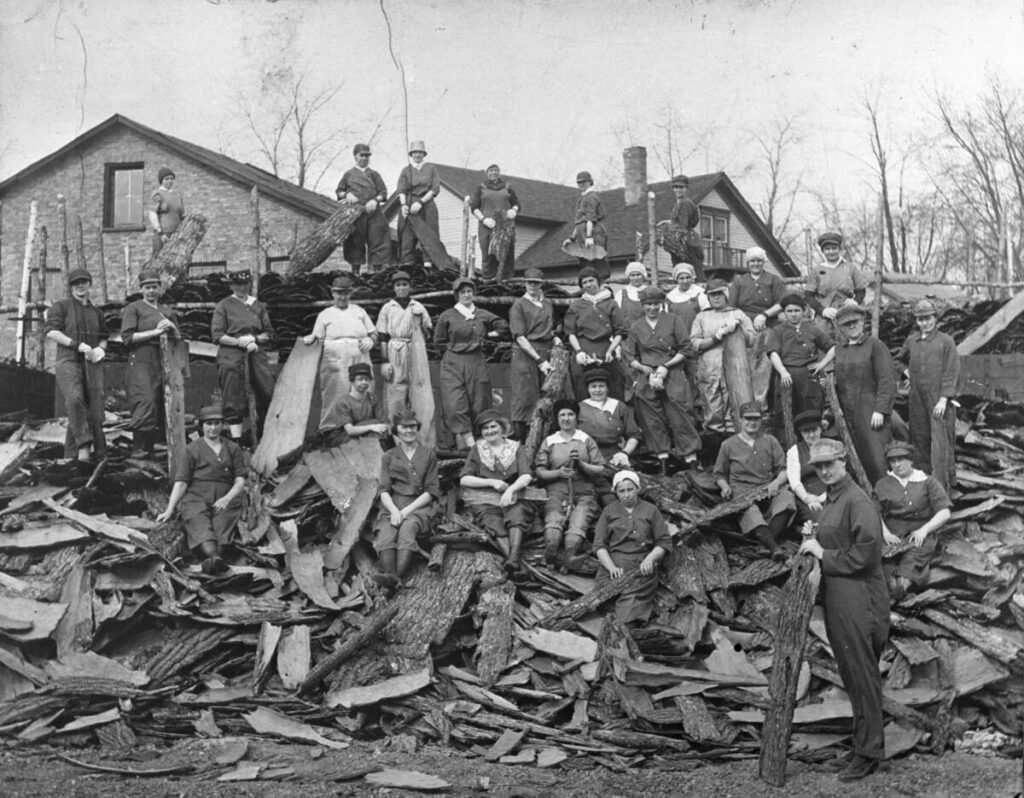

The cut-over areas of northern Wisconsin were ideal settings for tanneries. The region was already set-up for large scale logging operations, so transitioning from felling white pine to felling hemlocks was relatively simple. With the decimation of the white pine forests, there were also many former loggers in the region looking for employment, and a large labor pool made it easier for tanners, like the Shaws, to recruit people to work in their very smelly industry. Additionally, tanneries needed easy access to large amounts of water, so areas with many streams like Taylor County were appealing settings for tanneries.

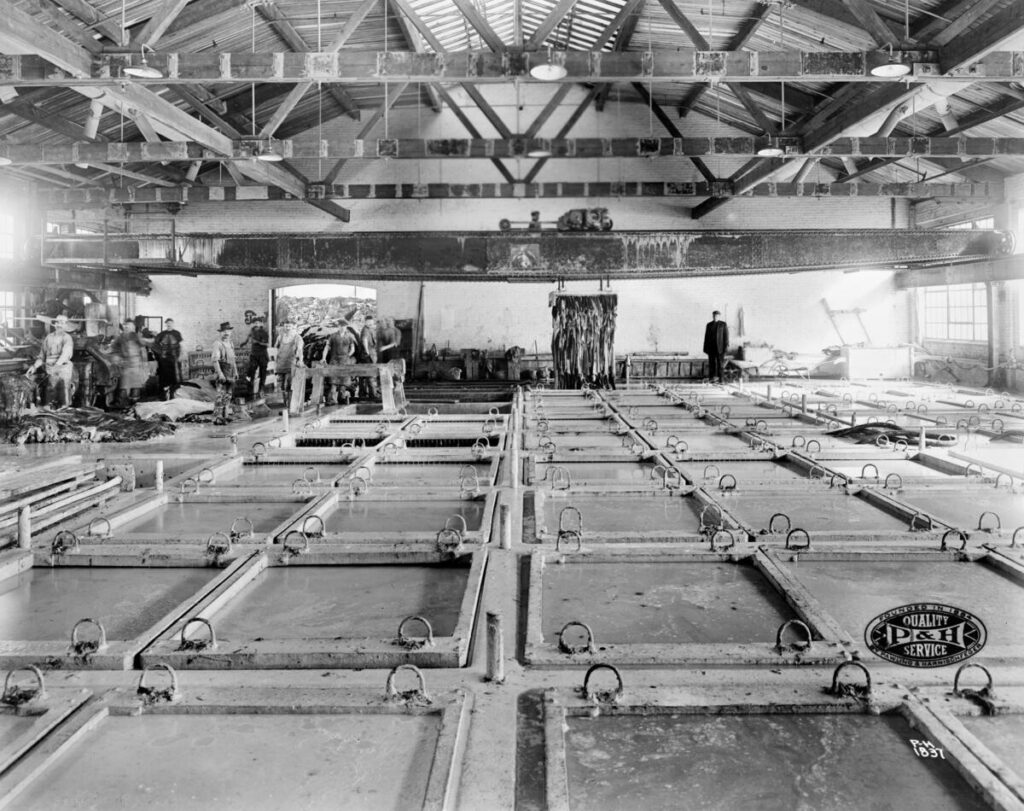

Soon, tanneries across Taylor County began to receive cow hides sent by the Shaw Family from locations as far away as South America. Though there were cows in Taylor County, the Shaw family primarily chose to ship hides from cattle herds in Central and South America as well as the American Southwest. It was cheaper to send the hides to Taylor County then to send the bark to where the hides were produced.

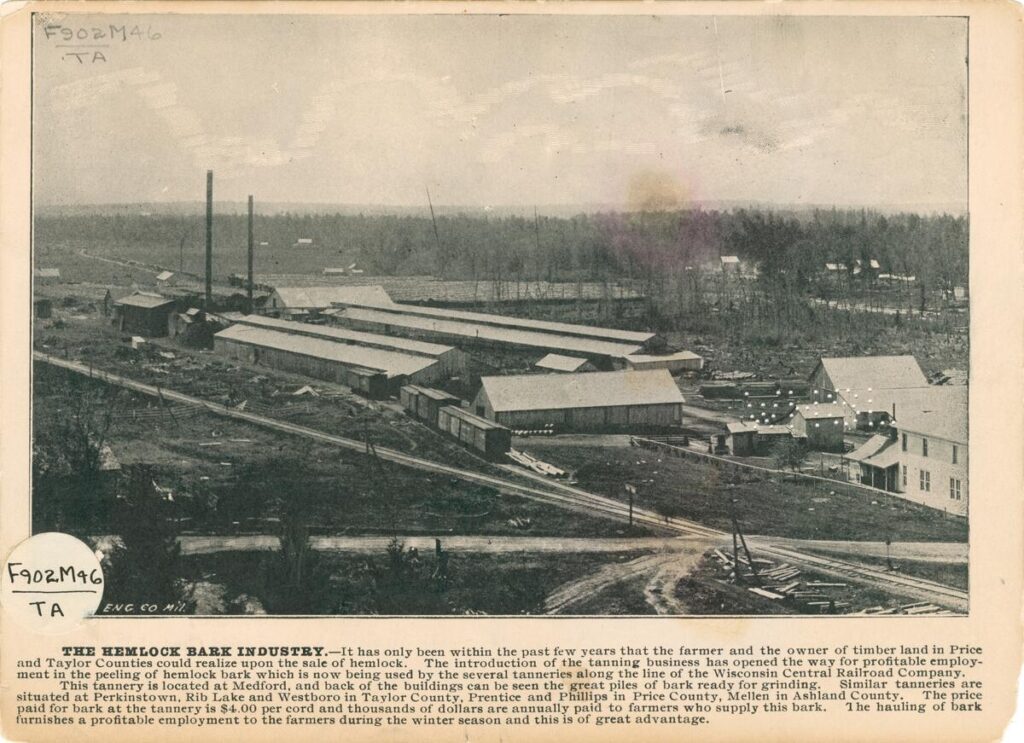

To meet the volume of hides, the Shaws contracted with local tanneries and built their own. Although they existed before the tanning industry, the communities of Medford, Rib Lake, and Perkinstown grew around the Shaw company tanneries. Workers at the Shaw family tanneries earned about $8 per week. By April 1890, the tannery in Medford produced more than two tons of tanned leather each day.

Tanning in Wisconsin

The conditions that made Taylor County the Shaw’s choice for leather production drew other tanners to the state as well. By 1900, Wisconsin produced nearly 15% of the nation’s tanned leather, with the majority of the tanneries centered in Milwaukee. Unlike the Shaw’s operation in Taylor County that worked with hides shipped from afar, in Milwaukee the tanning industry grew alongside the stockyards. Farmers and ranchers across the upper Midwest and American southwest, sent their cattle to Milwaukee and Chicago to be butchered and have their hides turned into leather. Tanners in Milwaukee imported bark from the cutover district, transporting it by rail to the tanneries outside the city.

By 1910, Milwaukee was the world’s largest center for leather production, but the industry rapidly declined over the next few decades as alternatives to tanning with bark became available. The tanneries in Taylor County also declined during that period, with the major operation in Medford shutting its doors in 1919.

When the tanning industry left Taylor County, the region turned to the paper industry and tourism. In this new era, the bark spud remained in use—now for peeling bark from poplar and aspen logs on their way to the paper mill or for peeling bark from trees to make rustic-style furniture and cabins.

From peeling hemlock bark for the tanning industry to peeling popple for the paper industry, the history of Taylor County residents peeling bark with bark spuds illustrates the creative ways communities adapt to a changing environment and economy.

Written by Hildegard Kuse and Loretta Kuse, April 2019.

How to: Tan Bark

This silent film, produced in Britain in 1924, shows the processes of tanning leather in the early 20th century.

Click on the video title (at left) to open in YouTube.